The purification treatment methods of purified aluminum profiles mainly include the following:

First, mechanical treatment

Mechanical polishing: The use of machines or hand tools to clean the surface of aluminum profiles, remove surface rough layers and pollutants, and improve the surface finish. This method is suitable for aluminum profiles with high requirements for surface finish.

Sand blasting: The sand blasting machine is used to blast the sand and impact the surface of the aluminum profile to clean the surface impurities and obtain the required roughness. Sandblasting can enhance the adhesion between the aluminum profile and the coating, providing a good basis for the subsequent surface treatment process.

Second, chemical treatment

Pickling: The use of an acidic solution to soak or spray aluminum profiles to remove surface oxides, oil and other contaminants. Water washing and neutralization are required after pickling to avoid damage to the subsequent process and the aluminum profile itself.

Alkali washing: Similar to pickling, alkali washing uses an alkaline solution to clean aluminum profiles. Alkali washing can effectively remove pollutants such as oil and metal ions, while not causing serious corrosion to the matrix of aluminum profiles.

Third, electrochemical treatment method

Anodizing: the aluminum profile is placed in the electrolyte solution as the anode, and a dense, porous and strong adsorption aluminum oxide film layer is formed on the surface of the aluminum profile through electrolysis. This film layer not only has a beautiful natural luster and smooth texture, but also significantly improves the corrosion resistance and hardness of aluminum profiles. Anodizing is one of the common surface treatment methods for purifying aluminum profiles.

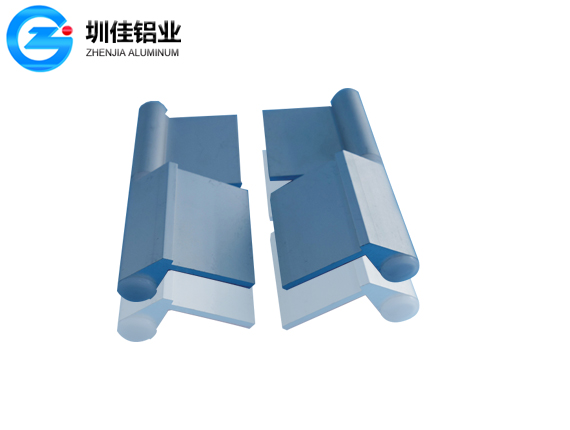

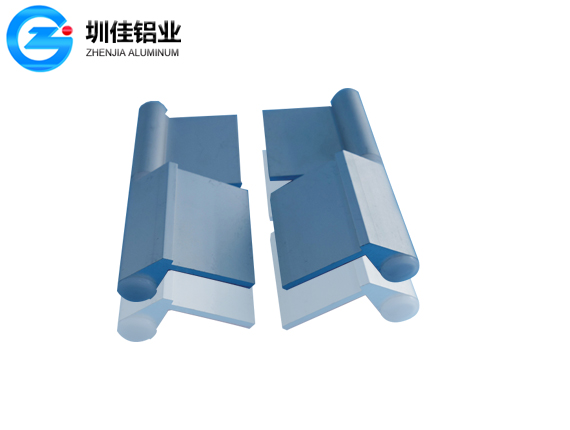

Purified aluminum profile

Electrolytic polishing: remove the rough layer and pollutants on the surface of the aluminum profile through electrolysis, making the surface smoother. Electrolytic polishing can further improve the surface finish and corrosion resistance of aluminum profiles.

4. Physical treatment method

Electrostatic spraying: The use of friction spray gun, under the influence of accelerating wind, the powder particles carry a positive charge when ejecting the gun body, contact with the negatively charged aluminum profile to produce electrostatic adsorption, and then through high temperature curing to form a strong surface coating. This method can effectively increase the surface and corrosion resistance of aluminum profiles.

Electrophoretic coating: on the basis of anodic oxidation, a resin film is further generated on the surface of the aluminum profile by electrophoresis, which is combined with the oxide layer to form a new composite film. Electrophoretic coating not only inherits the advantages of anodic oxidation, but also makes up for the lack of hardness.

5. Other treatment methods

Blowing method: The inert gas (such as nitrogen, argon, etc.) is passed into the interior of the aluminum melt to form bubbles and float up, taking away the hydrogen and some oxidizing inclusions in the melt to achieve the purpose of gas removal and impurity removal. This method is mainly used for the purification of aluminum melt.

Filtration method: Aluminum melt is passed through a filter made of neutral or active materials to separate solid inclusions suspended in the melt. The filtration method is usually used in combination with the blowing method to improve.