To ensure the quality of industrial aluminum profiles, we need to control them from the following aspects:

Raw material quality control:

Select high quality aluminum alloy raw materials to ensure that they meet production requirements

Strict inspection of raw materials, including appearance inspection, composition analysis, hardness testing, etc

Return or reprocess unqualified raw materials

Production process control:

Control melting temperature, time and atmosphere to ensure uniform alloy composition

The melting process is monitored and recorded in real time, and the parameters are adjusted in time

Ensure the stability of aluminum liquid temperature, flow speed and pressure during the casting process

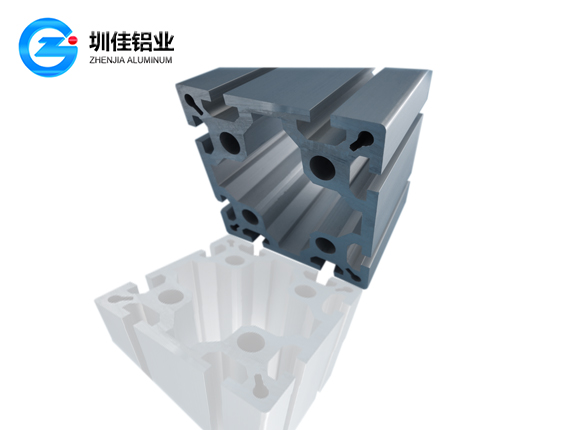

Strictly control the parameters and speed of the extruder to ensure the size and surface quality of the aluminum profile

Check the appearance and measure the size of the extruded aluminum profile to determine whether it meets the requirements

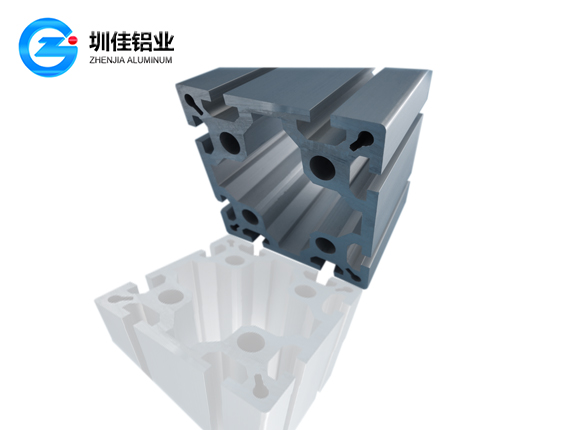

Industrial aluminum profile heat treatment and surface treatment:

Aluminum profiles are heat treated to improve their mechanical properties and corrosion resistance

The use of appropriate surface treatment methods, such as anodizing, sandblasting, spraying, etc., to improve the appearance of the product quality and durability

Quality inspection and control:

Appearance inspection, dimensional measurement and mechanical property testing of finished products

Regular maintenance and calibration of production equipment to ensure its normal operation

Establish a sound quality record and tracking system to trace the production status of each batch of products

Applications of statistical Process Control (SPC) :

The statistical process control is applied in the production process, and each production control point is divided into quality control point and process control point

The stability of the production process is evaluated by the control chart, and the satisfaction degree of the production process to various quality requirements is judged by the process ability index

A data acquisition system based on computer network is established to ensure the timeliness of data, and visual production log system is used to facilitate the tracking of quality problems

Quality Management System:

Establish quality policies and quality objectives and a system for achieving these objectives, such as ISO9000 family standards

Achieve quality policy and objectives through a range of activities, including quality planning, quality control, quality assurance and quality improvement

It can effectively control the quality of industrial aluminum profiles to ensure that they meet the needs of various application scenarios.